LNG Solutions

GasEntec delivers powerful, reliable LNG solutions that meet the evolving needs of the global energy market. We specialize in modular, mobile solutions across floating, onshore, and scalable projects—from small- to global-scale applications. Our portfolio of LNG patents underpins our innovative approach, ensuring that we deliver cutting-edge, efficient solutions worldwide.

GasEntec provides energy solutions that help solve complex energy challenges with a focus on performance, sustainability, and efficiency.

Integrated LNG Terminal Solutions

From LNG terminals to floating storage and regasification, we design, build, and operate cutting-edge solutions that deliver energy faster, safer, and more efficiently— regardless of geographical location or terrain.

Floating, Onshore, and Hybrid Terminal Solutions

Providing full-scale, end-to-end LNG solutions from design to commissioning, delivering LNG directly to power plants and industrial facilities through efficient virtual pipelines.

Product Line & Capabilities

RegasTainer™ Scalable, Modular Regasification for Any Terminal

Scalable, box-shaped regasification modules for plug-and-play installation and operations for offshore / onshore / jetty-based regasification requirements.

A decade ago, GasEntec conceived the first RegasTainer™ to modularize and standardize the regasification function of any LNG import terminal.

The RegasTainer™ comes in standard sizes and can be mounted on FSRUs, jetties or onshore, giving maximum flexibility to the terminal developer based on local conditions, while accelerating deployment because of its standardization.

Over time, GasEntec has productized a portfolio of other LNG terminal systems such as boil-off gas management, re-liquefaction, cooling, cargo handling, modular truck- and bus-loading bays, and other equipment.

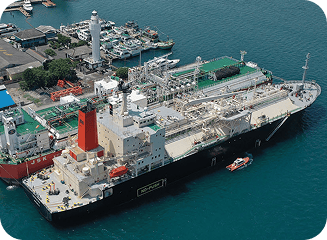

GasEntec plays a market-leading role by converting older LNG carriers into floating import terminals (FSRUs, FSUs, FRUs, JRUs) leveraging the RegasTainer™ and the other equipment in its portfolio to deliver a floating terminal quickly.

With a commitment to sustainability, GasEntec actively develops solutions that minimize the carbon footprint of LNG operations, ensuring a greener future for energy.

The company's innovative technology enables real-time monitoring and control of LNG regasification processes, enhancing safety and efficiency.

GasEntec collaborates with global partners to advance LNG infrastructure, promoting energy transition through strategic alliances in various regions.

Small-Scale FSRUs

(Floating Storage and Regasification Units)

Designed for smaller-scale projects, these units deliver high-efficiency regasification for regions where larger infrastructure may not be viable.

Large-Scale FSRU conversions

(Floating Storage and Regasification Units)

Converting LNG carriers into FSRUs and Floating Storage Units (FSUs) to meet large-scale import needs in high-demand areas.

Global-Scale LNG terminals

Comprehensive infrastructure solutions, including proprietary legged platform delivery systems for efficient LNG cargo handling and re-liquefaction technology.

O&M of Terminals and Infrastructure

Reliable O&M services that enhance efficiency, productivity, and safety while minimizing downtime.

Small-Scale LNG Carriers & Bunker Vessels

GasEntec provides end-to-end Engineering, Procurement, and Construction (EPC) packages for small-scale LNG carriers and bunkering vessels, designed with specialized cargo containment and gas supply systems.

LNGC-to-FSRU, FSU and FRU Conversion

Global leaders in converting LNG carriers to FSRUs, including longevity upgrades, repairs, equipment installation, and rigorous testing. Our solutions are optimized to meet site conditions and maximize operational lifespan.

LNG Cargo Handling Systems (CHS), Pressure Management, Cooling Tech, Re-liquefaction

Tailored CHS solutions for marine vessels that optimize performance and reduce costs. Features include integrated control systems, regas vaporizers, cryogenic controls, and more.

Tailored CHS solutions for marine vessels that optimize performance and reduce costs. Features include integrated control systems, regas vaporizers, cryogenic controls, and more.

Operation & Maintenance (O&M) of Terminals and Infrastructure

GasEntec offers comprehensive O&M services to maximize vessel and terminal performance, ensure cost predictability, and minimize downtime.

O&M Management

Preventive maintenance and operational support for efficient lifecycle management.

Inspection

Regular productivity and technical inspections ensure quality and adherence to specifications.

Technical Support

Post-commissioning technical evaluations with recommended improvements.

Maintenance & Spare Parts

Planned maintenance services with complete toolkits and spare parts for optimal performance.